A deck post base is that crucial piece of metal hardware connecting your vertical wood posts to the concrete footing. Its job? To stop the wood from ever touching the ground. This little connector is the unsung hero of a safe, long-lasting, and code-compliant deck.

The Unsung Hero of a Sturdy Deck

Look at any impressive deck, and you'll see the beautiful railings and the perfectly laid decking. But the real workhorse is hidden below. The deck post base is what ties the whole structure together, transferring the entire weight of your deck down to the solid foundation it’s built on.

Think of it like the chassis of a truck. It’s built to handle incredible forces, manage stress, and create a rock-solid connection between the frame and the ground. Without it, the whole thing would be dangerously unstable.

More Than Just a Bracket: The Three Core Jobs

A quality post base is doing three critical jobs at once. If you cheap out on any of these, you're putting your entire project at risk.

- Structural Support: This is its main gig. The base creates a rigid connection that anchors the vertical posts to the concrete footings. This stops them from shifting, lifting, or twisting under the weight of people, furniture, or even heavy winds. It’s what keeps your deck from wobbling.

- Moisture Protection: Wood’s number one enemy is moisture, which always leads to rot. Post bases are designed to lift the bottom of the post off the damp concrete, usually creating a crucial one-inch air gap. This standoff design is brilliant—it lets the vulnerable end grain of the lumber breathe and dry out, dramatically extending the life of your posts.

- Code Compliance: You can't just stick a post in concrete anymore. Building codes across the country are clear: structural posts cannot be in direct contact with the ground or concrete. Using a properly rated post base isn’t just good practice; it's a non-negotiable requirement to pass inspection and ensure your deck is safe and legal.

Setting the Stage for a Lasting Build

Picking the right hardware is where a successful build begins. While post bases are a huge part of the puzzle, you also need a solid grasp of the overall deck building process. Skimping here is not an option. Investing in quality, corrosion-resistant post bases and the correct anchors is fundamental.

A well-built deck is a system, and the post base is the anchor for that entire system. A failure at this one small point can lead to catastrophic results. Choosing durable hardware isn't just an expense; it's a critical investment in safety and peace of mind.

Ultimately, the entire strength and lifespan of your deck rest on these simple metal connectors. By understanding just how much they do, you can appreciate why settling for anything less than the best is a bad idea. For a solid start, you can find a huge range of reliable support for deck options at Xtreme eDeals, making sure your project is built on a dependable foundation from day one.

Decoding the Different Types of Post Bases

Choosing a post base isn’t a one-size-fits-all decision. The right piece of hardware really depends on your project's starting point—are you building on a pristine concrete slab, or are you about to pour fresh footings? Each type offers a specific solution, designed to provide stability and protection in different scenarios.

Matching the post base to the job is the first critical step toward a successful build. Let's walk through the most common styles you'll run into so you can confidently pick the perfect one.

Surface-Mounted Post Bases

Think of the surface-mounted post base as the go-to choice for existing surfaces. If you already have a solid, crack-free concrete patio or slab in place, this is almost certainly the style you’ll be reaching for. These bases are designed to be anchored directly onto that hardened concrete.

Installation is pretty straightforward. You just position the base, mark your holes, drill into the concrete, and secure it with the right anchors, like wedge or sleeve anchors. They come in all sorts of designs, from simple U-shaped brackets to more decorative options that can actually add to your deck's look.

A great example is the Nuvo Iron Post Base, which you can often find at retailers like Xtreme eDeals. These products do a great job of blending strength with a clean finish, giving you a secure mount that also looks sharp.

Cast-in-Place Post Bases

When you're starting from scratch and pouring fresh concrete footings, the cast-in-place (or wet-set) post base offers incredible strength. Instead of being bolted onto cured concrete, this type is set directly into the wet concrete mix itself.

As the concrete hardens around the base's anchor leg or strap, it creates a single, unified piece. This connection is incredibly strong and fantastic at resisting uplift from high winds. Honestly, it's one of the most secure foundations you can give a deck post.

The real magic here is integration. By embedding the anchor right into the footing, you’re making the hardware a true part of the foundation, not just something bolted on top. This creates a powerful, unified structural element.

This method does require some extra care to get the base perfectly level and aligned before the concrete sets, but the stability you get in return is well worth the effort.

Adjustable Post Bases

So, what happens if your surface isn't perfectly level? That’s where adjustable post bases come to the rescue. These clever designs have a threaded rod or plate that lets you make small height adjustments after the base is secured.

This flexibility is an absolute lifesaver. It lets you correct for slight variations in concrete height and helps you get a perfectly level beam across multiple posts. An adjustable base gives you that crucial margin for error, making the rest of the framing process much easier and more accurate. At Xtreme eDeals, we carry a range of adjustable post supports from brands like Decorex Hardware to solve this exact problem.

Standoff Post Bases

A standoff post base is less of its own "type" and more of a critical feature that every good outdoor post base should have. The design includes a small plate or tabs that elevate the wooden post by at least one inch off the concrete surface.

That little air gap is everything when it comes to longevity. It stops moisture from wicking up from the concrete into the vulnerable end grain of your post, which is the number one cause of rot. In fact, many building codes now mandate this standoff to ensure the durability and safety of the whole deck structure.

You'll see this feature in products from quality brands like Decorex Hardware, who understand how vital it is for a lasting build. The maturity of the broader deck and patio construction market shows a consistent demand for reliable hardware that stands the test of time, and you can dig into more insights on that trend over at IBISWorld.com.

To help you decide at a glance, here's a quick comparison of the main types we've discussed.

Quick Comparison of Deck Post Base Types

This table breaks down the core differences, making it easier to see which post base aligns with your deck project's specific needs.

| Post Base Type | Best For | Installation Method | Key Advantage |

|---|---|---|---|

| Surface-Mounted | Existing concrete slabs or patios | Bolted onto cured concrete with anchors | Easy installation on pre-existing surfaces |

| Cast-in-Place | New construction with fresh footings | Set directly into wet concrete during pouring | Creates an incredibly strong, integrated connection |

| Adjustable | Uneven or sloped concrete surfaces | Bolted down, with post height adjusted via a threaded mechanism | Allows for fine-tuning post height for a perfectly level frame |

| Standoff Feature | All outdoor wood posts on concrete | Incorporated into other base types (e.g., surface-mounted) | Prevents post rot by elevating wood off the concrete |

Ultimately, understanding these core designs is the first step. It empowers you to start your deck on a foundation that's not just strong and stable, but also engineered to fight off the elements for years to come.

Selecting Materials Built to Withstand the Elements

When you're choosing a deck post base, it's about so much more than just the shape or size. The material it’s made from is a critical decision that really dictates how long your entire deck will last. This one little piece of hardware is in a constant battle against moisture, corrosive chemicals leaching from treated lumber, and the full force of Canadian seasons.

Investing in the right material isn't just a good idea—it's your primary defence against premature rot and structural failure. Think of it as the armour for your deck's foundation. You wouldn’t go into a sword fight wearing cloth, so don’t use an underrated material for a job that demands serious resilience. The material you pick has to be tough enough to handle its specific environment, ensuring your deck stays safe and stable for years, not just a couple of seasons.

The Workhorse: Galvanized Steel

For the vast majority of deck projects, hot-dip galvanized steel is the undisputed industry standard, and for good reason. The process involves dipping raw steel into a bath of molten zinc, which creates a thick, protective coating that's metallurgically bonded to the steel. This isn't just a flimsy layer of paint; it's a tough, sacrificial barrier that stands up to the elements.

When you're shopping around, be sure to look for a G-185 coating. This specification tells you the hardware has a much thicker layer of zinc protection—1.85 ounces per square foot—which offers far better corrosion resistance than the lighter G-90 coatings you might see. It's the perfect choice for most Canadian climates and gives you excellent protection against the chemicals found in modern pressure-treated lumber.

When to Upgrade to Stainless Steel

Galvanized steel is a solid performer, but some situations demand an even higher level of protection. Stainless steel is the premium, no-compromise choice for decks facing the most corrosive conditions. If your deck is anywhere near the coast where it will be hit with saltwater spray, or if you're building around a saltwater swimming pool, stainless steel is non-negotiable.

This material contains chromium, which forms an invisible, passive layer on the surface that naturally resists rust and corrosion. Yes, it comes with a higher price tag, but that investment is often what stands between a long-lasting deck and one that starts deteriorating rapidly. Skipping stainless steel in these specific environments can lead to ugly rust stains and, far more dangerously, a compromised structural connection in just a few short years.

A deck post base isn't just holding up a post; it's resisting constant, invisible forces. The chemicals in treated wood and the minerals in groundwater are always trying to eat away at the metal. Choosing a material that can resist this relentless attack is fundamental to a long-lasting deck.

Powder-Coated Steel for Style and Substance

Sometimes, you need both brute strength and a specific look to match your deck's overall aesthetic. Powder-coated steel offers a fantastic blend of durability and visual appeal. The process involves applying a dry powder electrostatically and then curing it with heat. This creates a hard finish that's much tougher than conventional paint.

This finish provides a solid layer of protection against moisture and scratches while coming in various colours—most commonly black—to match other deck hardware like balusters and railing connectors. You'll find this finish on many high-quality options from brands like Nuvo Iron and Decorex Hardware, ensuring your post base deck connections look as good as they perform. With the composite decking market's explosive growth, there's a growing demand for durable, compatible hardware, a trend detailed in market research from Polaris Market Research.

Ultimately, the goal is to build a secure foundation that lasts. You can find a complete selection of reliable fasteners and fittings at Xtreme eDeals, ensuring every connection in your project is built with materials designed to endure.

When you’re staring at a wall of hardware, it’s easy to get overwhelmed. But once you’ve settled on the right material for your post bases, the next challenge is matching that hardware to your deck’s actual design. This isn't just about looks—it’s about translating your blueprint into a rock-solid foundation.

Getting the sizing and load calculations right is what separates a deck that feels solid underfoot from one that wobbles with every step. It’s all about making sure your post base fits your post perfectly and can handle the immense weight of the structure above it. This is where every measurement counts, ensuring the entire deck can safely transfer its load down to the footings.

Sizing Up Your Posts for a Perfect Fit

The connection between your lumber and its metal base needs to be snug. A post base labelled for a 4×4 post isn't just a suggestion—it's engineered specifically for the actual dimensions of finished lumber. A standard "4×4" post that you buy at the store is really closer to 3.5 by 3.5 inches, and the post base is built to cradle those exact measurements.

Trying to use a 6×6 base for a 4×4 post creates a dangerous gap. That slop allows the post to shift and twist, which is the last thing you want at a critical connection point. The goal is to eliminate any movement, which is why a tight, accurate fit is non-negotiable. Always measure your posts and buy a base designed for that specific size.

Understanding Load Capacity and Your Foundation

Every piece of deck hardware has its limits. A post base is rated to handle a specific amount of weight, known as its load capacity. This isn’t just about the static weight of the lumber, decking, and railings (the dead load). It also has to safely manage the ever-changing weight of people, furniture, heavy snow, and even wind (the live load).

Think of your post base as a funnel. Its job is to channel all that combined weight from the post directly into the concrete footing beneath it. If the base isn't rated for the expected load, it becomes the weak link in your support system. This is a massive safety issue, especially for second-storey decks or those in snowy climates.

The relationship between your post base, post, and footing is a chain of command for managing weight. The beam transfers load to the post, the post transfers it to the base, and the base transfers it to the footing. A failure at any point in that chain compromises everything above it.

This is especially important given that homeowners and DIYers are the primary builders of decks. In fact, the residential sector accounts for the majority of wooden decking volume, which makes clear guidance on technical topics like load capacity absolutely essential. You can dig into more of these decking market trends at MordorIntelligence.com.

The Critical Role of Footings and the Frost Line

The post base is only half of the foundation puzzle—the concrete footing it sits on is the other. The size and depth of this footing are dictated by two simple things: the load it needs to support and your local climate.

In Canada, building codes are very clear: footings must extend below the frost line. This is the maximum depth that groundwater in the soil is expected to freeze during a cold winter. Why does this matter so much? When water in the soil freezes, it expands with incredible force, "heaving" the ground upwards. If your footings are too shallow, this seasonal movement will lift and twist your entire deck, causing serious structural damage.

The footing also needs to be wide enough to spread the deck's load over the soil without sinking. Your local building department will have specific requirements for footing dimensions based on your deck’s size and local soil conditions. Always check these codes before you grab a shovel. A strong post base on a weak footing is just a recipe for failure.

Getting the Installation Right: Best Practices and Mistakes to Avoid

Choosing the right hardware is only half the battle. Even the toughest post base will fail if it’s installed poorly, and a shoddy installation can put your entire deck project at risk. Let's walk through the essential steps and, more importantly, the critical mistakes that can compromise the safety and longevity of your deck.

Knowing what not to do is just as important as knowing what to do. Get these details right the first time, and you'll save yourself a world of future headaches and ensure your deck stands on a truly solid foundation.

Prepping for a Rock-Solid Installation

Success starts long before you pick up a drill. A secure connection depends entirely on proper preparation of the concrete surface. Make sure your concrete is fully cured, clean, and completely free of dust, loose debris, or any crumbling sections.

A critical, and often overlooked, first step is ensuring the ground itself is properly prepared. This includes precise footings excavation to give your concrete a stable base that won’t shift over time. Trying to install a post base on cracked, weak, or uneven concrete is a recipe for disaster. The anchors simply won't have solid material to grip, leading to wobbly, unsafe posts.

Once the surface is ready, it's all about the layout.

- Measure and Mark: Use chalk lines to snap a precise grid for your post locations. Always double-check your measurements from multiple points to make sure everything is perfectly square.

- Position the Base: Place the post base exactly on your marks. Use a pencil or marker to trace the anchor hole locations directly onto the concrete.

- Drill with Precision: Grab a hammer drill and a masonry bit of the correct diameter. Drill your holes to the depth specified by the anchor manufacturer. This next part is crucial: you must clear all the dust out of the holes with a brush or compressed air. If you don't, the anchor can't engage properly.

Common Installation Pitfalls and How to Sidestep Them

Knowing the common mistakes is your best defence against making them. I've seen countless DIY builders focus on the big picture, only to overlook a small installation detail that has huge consequences down the road.

Mistake #1: Using the Wrong Fasteners

This is probably the most dangerous error you can make. Attaching a post base to the footing with standard wood screws or underrated fasteners is asking for trouble. Those screws just aren't designed to handle immense structural forces, especially uplift from high winds. Always use structural-grade anchors specified for concrete. For securing the post to the base, use the through-bolts or heavy-duty structural screws recommended by the hardware manufacturer.Mistake #2: Ignoring the Standoff

Many high-quality post bases feature a built-in 1-inch standoff. This isn't just for looks—it's essential. That small gap allows the vulnerable end grain of your wood post to dry out, which is your number one defence against rot. Placing the post directly on the concrete traps moisture and practically guarantees premature failure.Mistake #3: Forgetting to Check for Plumb

Once you've placed the post in the base, it absolutely must be perfectly vertical, or plumb. Use a level on at least two adjacent sides of the post before you permanently fasten it. A post that’s even slightly off-plumb transfers loads unevenly and creates an unstable, unprofessional-looking structure. A good trick is to brace the post temporarily to hold it in position while you secure everything.

A post base installation is a chain of dependencies. A strong anchor is useless in weak concrete. A perfect base fails if the post isn't plumb. Every single step—from cleaning the surface to tightening the final bolt—contributes directly to the final strength and safety of your deck.

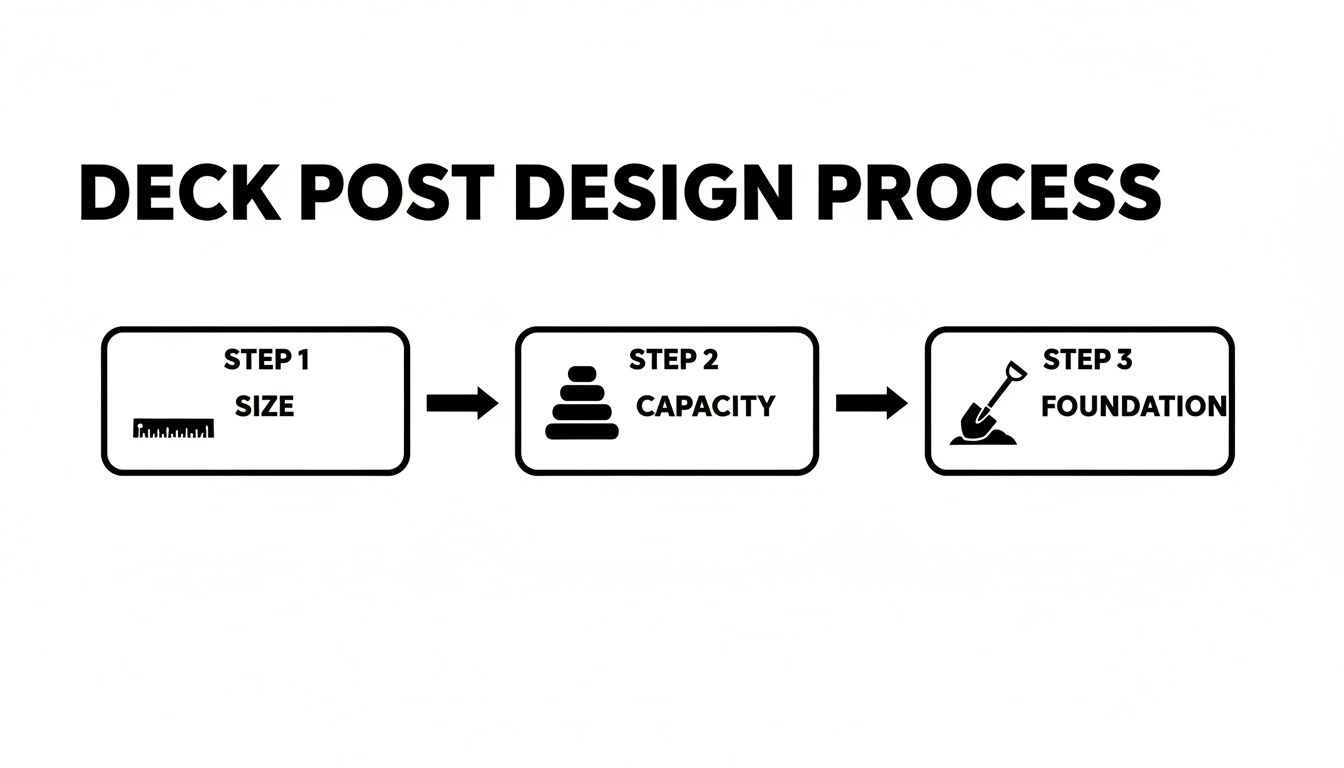

To help you visualize how all these pieces fit into the bigger picture, here’s a quick breakdown of the core design process.

This flowchart really drives home the point that a successful build depends on a sequence of correct decisions, where each step builds upon the last.

Selecting the Right Anchors for the Job

Your connection to the concrete is only as strong as the anchors holding it down. For this job, the two most common workhorses are wedge anchors and sleeve anchors. You can find a complete selection of these crucial fasteners at Xtreme eDeals, ensuring you start your project with the right gear from the get-go.

Choosing the correct type and size is non-negotiable. To dive deeper into what makes these fasteners tick, check out our detailed guide on https://xtremeedeals.ca/wedge-anchors-in-concrete/. By avoiding these common pitfalls and sticking to best practices, you can ensure your deck’s foundation is as strong and durable as the memories you'll build on it.

Your Questions About Deck Post Bases Answered

Even the best-laid plans run into questions once the sawdust starts flying. Let's tackle some of the most common queries that come up during a deck build. My goal here is to clear up any confusion so you can move forward with confidence.

Do I Really Need a Post Base for My Deck?

Yes, absolutely. This is non-negotiable. Modern building codes are crystal clear on this: structural wood posts cannot touch concrete or dirt directly. The post base is that critical piece of hardware that lifts the wood off the concrete, stopping moisture from wicking up into the end grain. That moisture is what starts rot, the number one enemy of any deck foundation.

But it’s not just about rot. The base creates a solid, load-rated connection between the post and its footing. This mechanical link is what helps your deck resist sideways forces and wind trying to lift it, keeping it stable and safe for years. Skipping this hardware isn't just cutting a corner; it's a major structural and safety hazard that's guaranteed to fail a building inspection.

What's the Difference Between a Standoff Post Base and a Standard One?

The real difference comes down to one crucial detail: elevation. A standard, flat-style base holds the post almost flush with the concrete. A standoff post base, on the other hand, is specifically engineered to lift the bottom of the post at least an inch off the surface. Honestly, most quality post bases you'll find today are standoff bases for this very reason.

That one-inch air gap is a total game-changer for your deck’s lifespan. It allows the most vulnerable part of the post—that thirsty end grain—to completely dry out after a rainstorm. This simple design feature dramatically cuts down the risk of rot, adding years to the life of your deck's support system. For pretty much any outdoor deck in Canada, a standoff base isn't just the better choice; it's often what the code demands.

Think of a standoff base as giving your posts their own pair of waterproof boots. It keeps them elevated out of the puddles, ensuring they stay dry and strong instead of slowly deteriorating from constant contact with moisture.

Can I Install a Post Base on an Existing Concrete Patio?

You can, but you've got to do your homework before drilling any holes. First, check the concrete itself. Is the slab thick enough (usually at least four inches) and in good shape? Any big cracks, crumbling edges, or signs of frost heave are serious red flags.

Second—and this is the big one—you need to know if the slab has proper footings directly under where you plan to put your posts. Most patios don't. For a small, floating deck that's low to the ground, you might be okay. But for any larger, load-bearing deck attached to your house, you will almost certainly need to cut through the patio, dig down, and pour new concrete footings that go below the frost line. This is the only way to properly support the structure and satisfy local building codes.

What Kind of Fasteners Should I Use to Attach the Post to the Base?

This is one of those details you have to get right for safety's sake. You can never use regular deck screws or nails to connect the wood post to the metal base. They simply aren't designed to handle the structural loads and can shear off or pull out, which could lead to a catastrophic collapse.

You need to use fasteners that are specifically engineered to handle shear and uplift forces. Your best bets are:

- Through-Bolts: A bolt that goes all the way through the post with a washer and nut on the other side is one of the strongest connections you can make.

- Structural Screws: These heavy-duty, load-rated screws are a fantastic, code-approved option and are very popular with builders.

- Lag Screws: The right size and length of galvanized lag screw is also a common and reliable choice.

Always, and I mean always, read the post base manufacturer’s instructions. They will tell you exactly what type, diameter, and length of fastener to use to get the load rating they advertise. Think of it as a complete system; using the wrong parts breaks the whole thing.

The foundation is the most important part of your deck, period. For a complete selection of high-quality post bases, structural screws, and concrete anchors from trusted brands like Nuvo Iron and Decorex Hardware, look no further than XTREME EDEALS INC. Start your project on solid ground by visiting us at https://www.xtremeedeals.ca.

Leave a comment

You must be logged in to post a comment.